SIPs

What are SIPs?

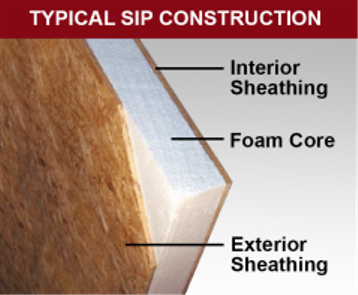

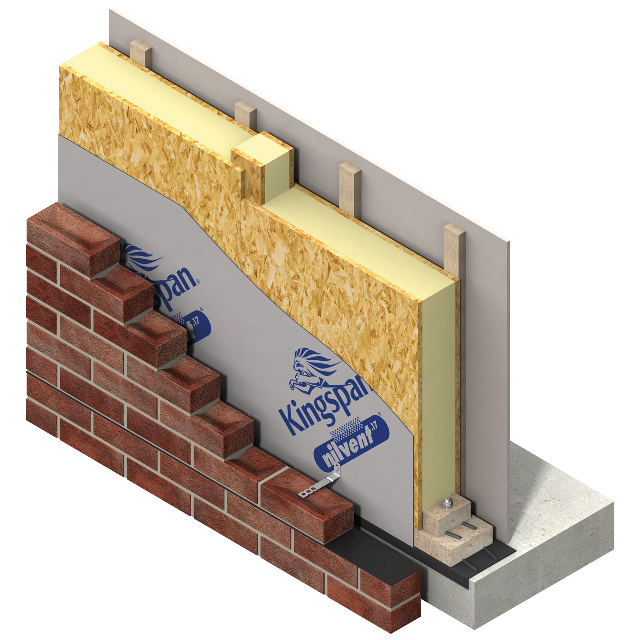

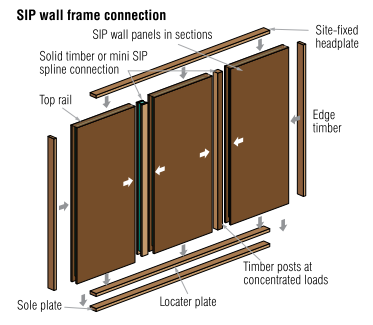

Structural insulated panels (SIPs) are high- performance building panels used in floors, walls and roofs for residential and light commercial buildings. The panels are made by sandwiching a core of rigid foam insulation between two structural facings, such as oriented strand board (OSB). Other skin materials can be used for specific purposes. SIPs are manufactured under factory controlled conditions and can be custom designed for each project. The result is a building system that is extremely strong, energy-efficient and cost effective. Building with SIPs will save you time, money and labour.

Why choose SIPs over traditional methods?

The main benefits to building with SIPs are:

• Superior insulation provides improved energy efficiency which reduces heating and cooling costs.

• Installation time can be reduced up to 55 to 60% against traditional construction therefore minimising overall onsite

costs due to reduced; project management, plant hire, welfare facilities and most importantly labour.

• Factory-controlled manufacturing provides a consistent and accurate engineered product allowing for easier and precise

installation.

• Offsite manufacture results in less waste on site.

• Panels can be built in to large format walls prior to site delivery therefore reducing installation time.

• Up to 7 times stronger when compared to timber frame construction.

How much time can be saved building with SIPs?

SIP homes go up much faster than traditionally framed buildings. A properly trained

SIP installation crew can cut framing time by 55 percent compared to conventional

wood framing. Panels are

manufactured as big as 8- by 24-foot, so entire wall and roof sections can be put up quickly, reducing dry-in time. SIPs are ready to install when they arrive at the jobsite, eliminating

the time needed to perform the individual jobsite operations of framing, insulating and

sheathing stick-framed walls. Electrical chases are typically provided in the core of panels,

so there is no need to drill through studs for wiring.

How much

money can be saved building with SIPs?

Builders can save money through decreased construction and labor costs. A high-

performance building envelope often allows HVAC equipment to be downsized and

ductwork to be minimized. Builders can also significantly reduce jobsite waste disposal and

temporary heat during construction. Homeowners that incorporate other energy-efficient

features into a SIP home can see utility savings of 50 percent or more. In a 2021 example

for a typical 2,000 sf home, using SIPs saves over $16,000 in eliminated 2 x 4 raw material

costs alone due to the high costs of lumber vs OSB used for SIPs.

How sustainable

are SIPs?

Structural insulated panels are one of the most environmentally responsible building

systems available. A SIP building envelope provides continuous insulation, is extremely

airtight, allows for better control over indoor air quality, reduces construction waste, and

helps save natural resources. Life cycle analysis has shown that SIP homes have a

tremendous positive environmental impact by reducing energy use and greenhouse gas

emissions throughout the home’s life cycle. SIP designs can save 45% more CO2 with

a 5.1 year energy payback and a 3.8 year greenhouse gas payback compared to stick

framing examples.

How strong

are SIPs?

The structural characteristics of SIPs are similar to that of a steel I-beam. The OSB facers

act as the flange of the I-beam, while the rigid foam core provides the web. This design

gives SIPs an advantage when handling in-plane compressive loads. SIPs are used for

high wind designs in excess of 180 mph. The load-bearing area of SIPs is equivalent to building with

2x10 framing at 16 inches on center.

R-values for SIPs depend on the thickness of the SIP and the type of core material that is

used. The overall R-value of an exterior wall made with SIPs also depends on the cladding and interior finish applied to the SIPs. But SIPs on their own already have very high R-values:

| Panel thickness (mm) | 100 | 125 | 150 | 175 | 200 | 225 |

| U-value (W/m2K) | 0.37 | 0.27 | 0.21 | 0.18 | 0.15 | 0.14 |

| R-value (m2K/W) | 2.7 | 3.7 | 4.8 | 5.6 | 6.7 | 7.1 |